Paving the Future of Building

The construction industry stands on the brink of a transformation, driven by advancements in 3D printing technology. This revolutionary method, also known as additive manufacturing, promises to reshape how structures are designed, built, and maintained, offering unprecedented efficiencies and capabilities. In this article, we explore the impact of 3D printing in construction, highlighting its benefits, challenges, and future prospects.

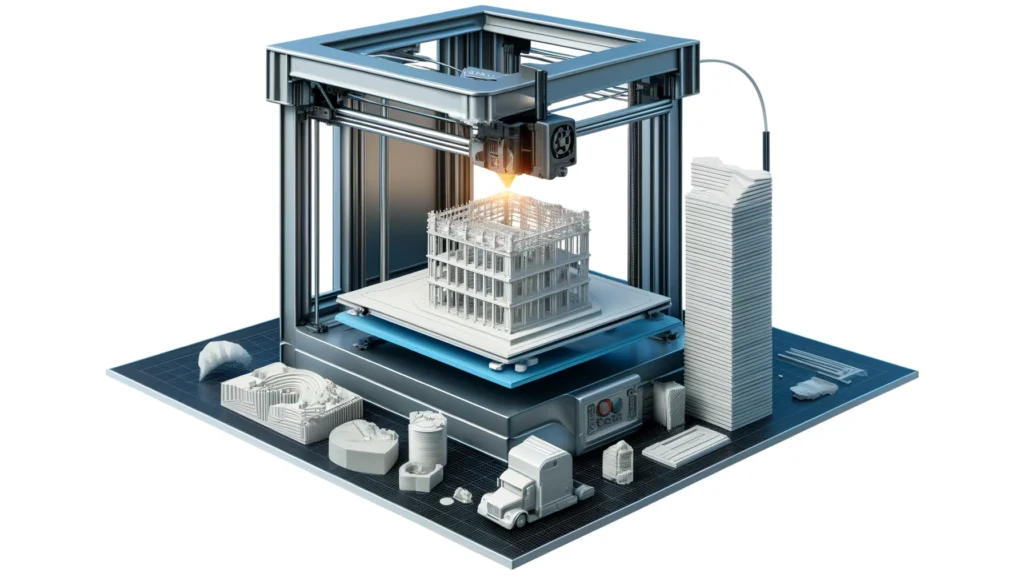

What is 3D Printing in Construction?

3D printing in construction refers to the use of additive manufacturing techniques to fabricate buildings or construction components directly from digital models, using layer-by-layer material deposition. This technology employs various materials such as concrete, plastic, and metal, paving the way for innovative architectural forms and smarter construction methods.

Efficiency and Speed

3D printing significantly reduces the time required to construct buildings. Components can be produced and assembled within days instead of weeks or months, thereby speeding up the overall construction process.

Cost Reduction

This technology minimizes labor costs as fewer workers are needed on site. It also reduces waste production since materials are used more precisely.

Design Flexibility

Architects and designers are no longer confined by traditional manufacturing constraints and can create complex, innovative, and customized designs.

Sustainability

3D printing promotes sustainability as it allows for the use of eco-friendly materials and significantly reduces waste compared to conventional construction methods.

Applications of 3D Printing in Construction

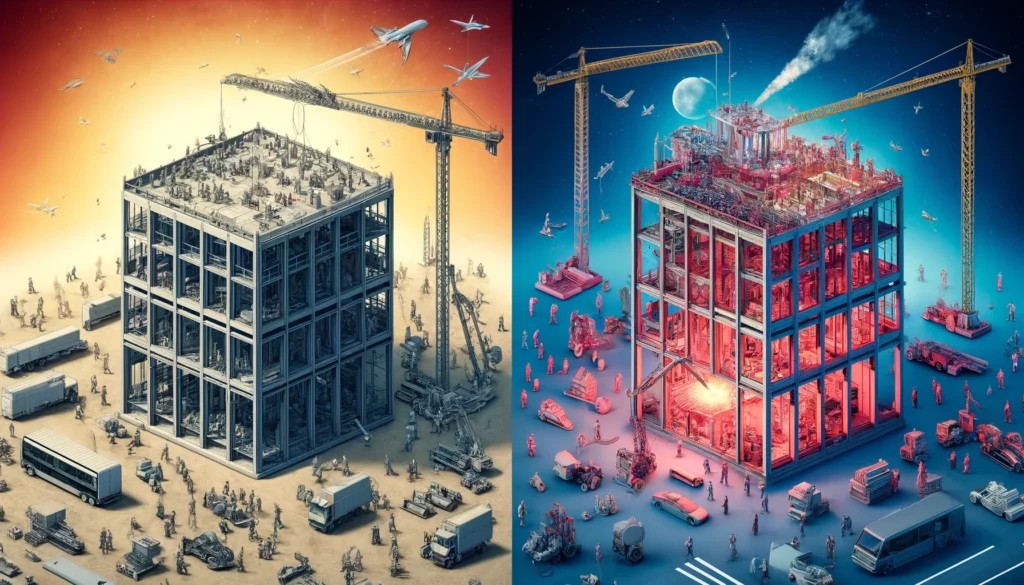

Residential and Commercial Buildings

Several projects around the world showcase the potential of 3D printing in constructing residential and commercial buildings quickly and affordably.

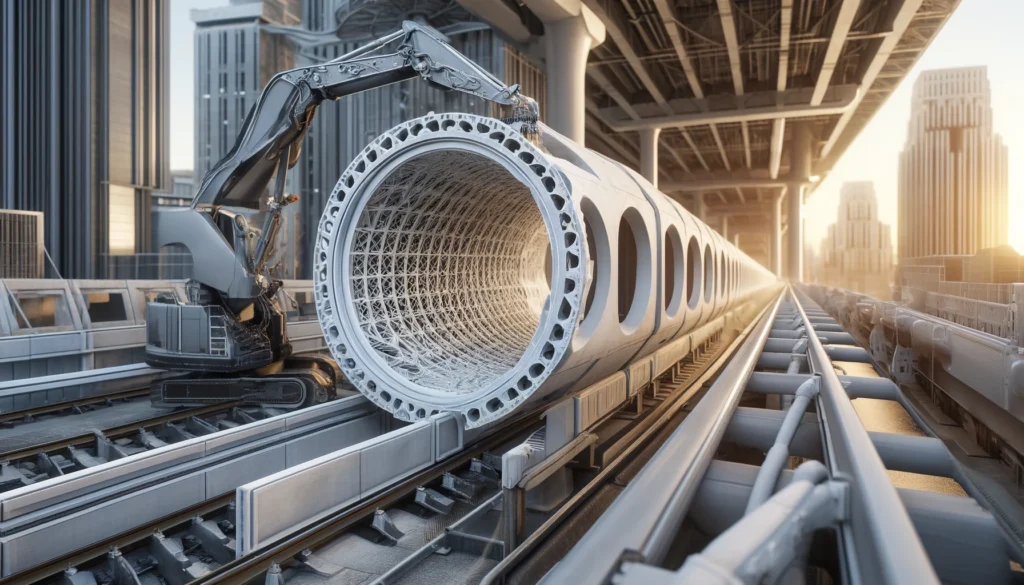

Infrastructure

3D printing is also being used to create complex components for bridges and overpasses, demonstrating enhanced strength and durability.

Customized Components and Furniture

From tailored wall panels to bespoke furniture, 3D printing offers the ability to customize designs and functional elements within buildings.

Challenges and Limitations

While 3D printing in construction offers numerous benefits, there are several challenges that need to be addressed:

- Material Limitations: The range of suitable materials is currently limited, affecting the types of projects that can be undertaken.

- Technical Challenges: Scaling up 3D printing for large-scale construction requires further technological advancements.

- Regulatory Hurdles: Building codes and standards still need to be updated to fully accommodate 3D-printed structures.

The Future of 3D Printing in Construction

The future of 3D printing in construction looks promising. With ongoing research and development, the scope of this technology is expected to expand, leading to smarter, more resilient, and more sustainable construction practices.

Conclusion

3D printing is set to revolutionize the construction industry by offering new possibilities for design, efficiency, and sustainability. As the technology continues to evolve, it could soon become a standard practice in construction, shaping the cities of the future.